What is Powder Coating?

Steven RulloShare

What is Powder Coating?

We have many years of experience in the metal fabrication industry and find that sometimes we take if for granted that our customers know what we are talking about when we use industry jargon. Powder coating is one of the industry processes for which we speak about like it is second nature to everyone.

Like any specialty field, there are processes and terms that are metal specific. If you're not familiar with the metal fabrication industry it may seem a bit daunting, but you don't have to be a metallurgist to know enough to follow along and make some good decisions!

A question that we have customers asking for some clarification about is powder coating. We are happy to shed a bit of light on this topic. We'll keep it simple as our goal is to inform our customers regarding powder coating as it applies to our metal signs and decor, and not to make this an in depth lesson.

We choose powder coating as our means of painting our signs and décor for multiple reasons. Most of our signs are made of steel. As you may know, steel will nearly immediately begin to oxidize (rust) when left exposed to air, moisture and other elements. We give an option on many signs to leave the sign raw steel, with the intention of it rusting over time. However, we need to protect that steel if we do not want rust.

We protect our steel signs with the most durable paint application that is also cost effective. Hence, powder coat paint is applied providing a protective layer from moisture and the elements. It also offers a stylish accent with the many colors that are now available as powder coating becomes more and more popular.

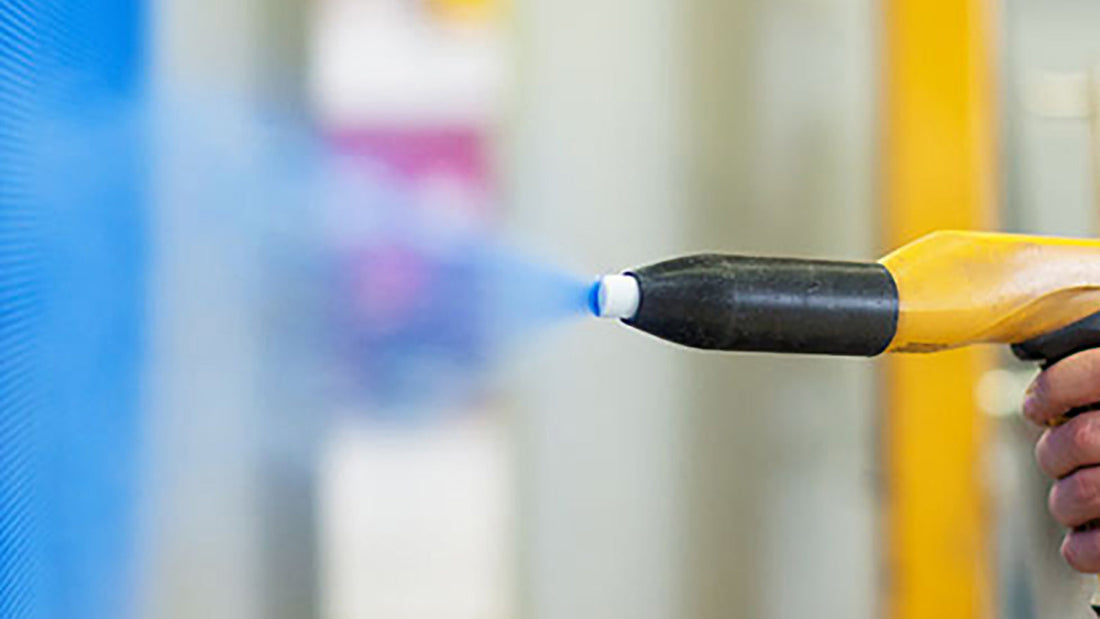

Powder coat paint is applied in a dry, powder form to the steel signs. The trick is to get the powder to "adhere" to the metal and this is done so using the proper powder coat application gun. This equipment provides an electrical charge to the metal sign that makes the powder "stick" to the part being painted. The coated sign is then placed in an oven and the sign is heated to a temperature that cures the powder, causing it to become a liquid and then bake to a solid again. This temperature can vary a bit between manufacturers, but is around 425 degrees or so. Once the temperature is reached for a specified length of time, the signs are air cooled and the process is complete.

This baked-on process yields a durable finish superior to other paints. It is also a relatively clean process environmentally speaking, especially compared with other wet-applied applications. For our purpose, it offers our customers a durable finish for our metal signs. We believe it provides our customers the best quality which is our goal every step along the way from taking a sign from idea to finished product.

Shop our variety of metal signs and decor today. As always please contact us to let us know if we can help!